By WETACTICS Outdoor Gear Lab

In the world of outdoor tools, steel choice defines a knife’s character — whether it’s sharper, tougher, more rust-resistant, or easier to maintain.

When shopping for knives, you may often see designations like 5Cr15, 8Cr13, 440C, or D2. These codes aren’t random; they represent the chemical composition and performance of the steel.

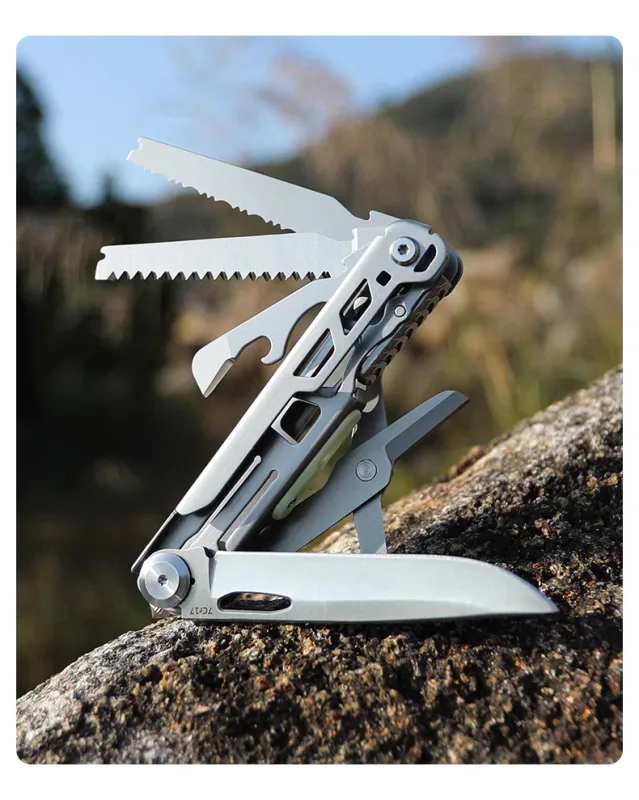

How to Choose a Reliable Outdoor Multi-Tool?

Let’s take an objective look at these common knife steels and their ideal applications.

1. 5Cr15: A Balanced Choice for Everyday and Light Outdoor Use

5Cr15 (or 5Cr15MoV) is a stainless steel with moderate carbon content, offering good corrosion resistance and toughness.

Key features:

- Strong rust resistance — high chromium content ensures stability in humid environments.

- Easy to sharpen — can be restored quickly after dulling.

- Good toughness — less prone to chipping or cracking.

- Moderate hardness (around 55–57 HRC) with average edge retention.

👉最适合:厨刀、轻型露营工具和多功能钳子。

如果您主要用途是日常或轻度户外活动,5Cr15 性价比极高。

https://www.wetactics.com/index.php/product/20-in-1-camping-multitool-with-fire-starter/

2. 8Cr13: The Sweet Spot Between Sharpness and Durability

8Cr13MoV builds upon 5Cr15 with higher carbon and vanadium content, balancing sharpness and wear resistance.

Advantages:

- Sharper edge with longer retention.

- Cost-effective, widely available and easy to process.

- Good machinability, suitable for mass production and maintenance.

However, it’s less corrosion-resistant than 5Cr15, so regular cleaning is recommended in coastal or humid areas.

👉 Best for: EDC folding knives, camping knives, and entry-level tactical blades.

3. 440C: The Classic Stainless Benchmark

Once regarded as a premium stainless steel, 440C remains a trusted standard.

Highlights:

- High hardness (58–60 HRC) — retains sharpness for long periods.

- Excellent corrosion resistance.

- Harder to machine, resulting in slightly higher cost.

Its toughness is lower, meaning it can chip under heavy chopping or impact.

👉 Best for: mid-to-high-end outdoor, tactical, or diving knives.

4. D2: High Hardness and Wear Resistance — The “Semi-Stainless” Steel

D2 steel is well known among knife enthusiasts. Technically, it’s not a true stainless steel but a high-carbon, high-chromium tool steel.

Pros:

- Very high hardness (60–62 HRC) and excellent edge retention.

- Outstanding wear resistance, ideal for repeated cutting and demanding outdoor tasks.

Cons: - Limited corrosion resistance, requires regular oiling.

- Hard to sharpen, needs maintenance skill.

👉 Best for: professional tactical knives, survival blades, and heavy-duty multi-tools.

It’s a “pro-user steel” — extremely capable, but it rewards those who care for their gear.

5. Choosing the Right Steel for Your Needs

There’s no “best” steel — only the right one for your usage balance.

| Use Scenario | Recommended Steel | Why |

|---|---|---|

| Light outdoor / daily carry | 5Cr15, 8Cr13 | Easy to maintain, good rust resistance |

| General outdoor / multi-use | 440C | Balanced performance, solid durability |

| Heavy-duty / tactical survival | D2 | Maximum hardness and wear resistance (requires care) |

When choosing, consider your environment (humid or dry), frequency of use, and maintenance habits.

Like picking a car — SUVs and sedans each excel in their own way — the key is finding what fits you best.

Conclusion

Steel is only one part of what defines a knife.

Heat treatment, structural design, and machining precision all play major roles in real-world performance.

Understanding materials is the first step — choosing wisely ensures your tool becomes a dependable partner outdoors.